Explore Our Services and Solutions

Delivering Value to Our Ecosystem

Procure Ease

Bridging Businesses and the Best Raw Material Sources with Perfect Industrial Procurement Solutions Stronger Together with features Group Buying

E-Cloud Manufacturing

Pioneering the Future of Manufacturing: Discover higher levels of process efficiency and agility with our manufacturing services, shaping the future of the production industry.

Global Trade

Seizing Global Opportunities with Local Expertise: Optimizing Trade for Your Business Success

Credit Flow

Pioneering Growth Opportunities, Securing Supply, Unlocking Business Potential through Smart Supply Chain Financing

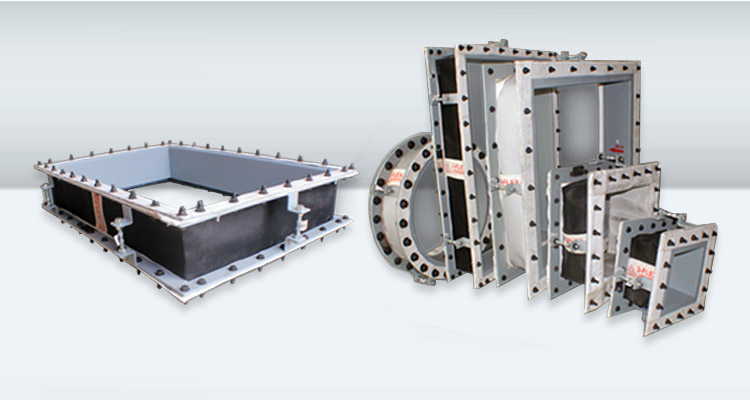

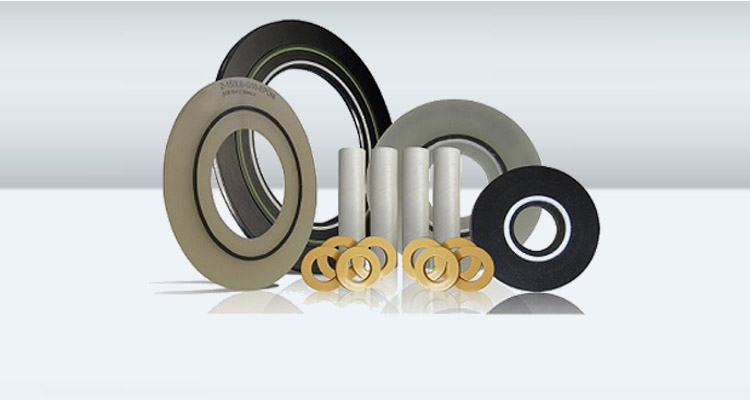

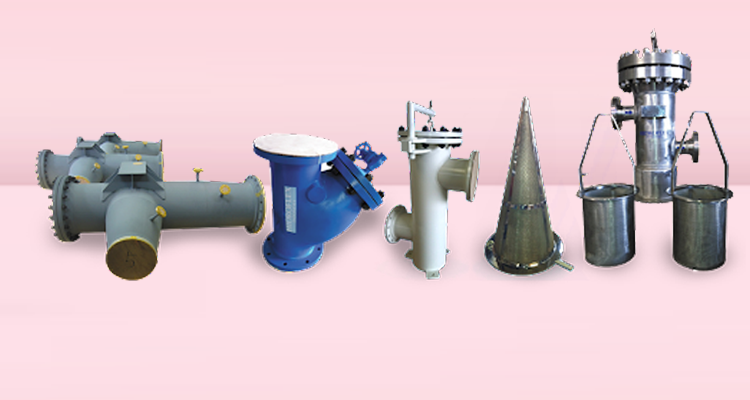

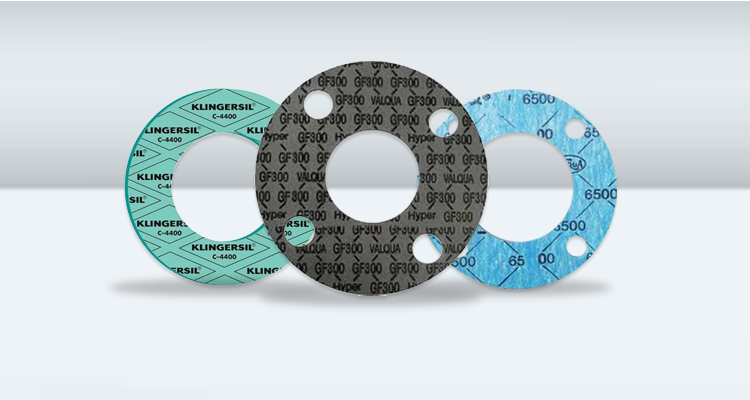

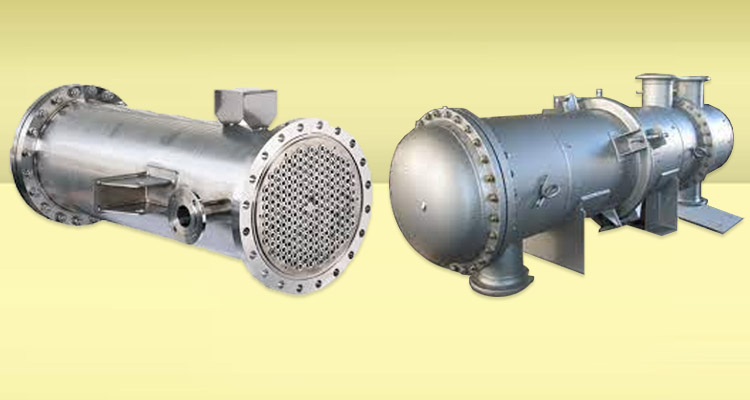

Explore Categories

Explore a Wide Range of Standard Industrial Products and Fabrication

Our Comprehensive Solutions for Your Business Growth

Procure Ease

Bridging Businesses and the Best Raw Material Sources with Perfect Industrial Procurement Solutions

Stronger Together with

features Group Buying

Stronger Together with

features Group Buying

E-Cloud Manufacturing

Pioneering the Future of Manufacturing:

Discover higher levels of process efficiency and agility with our manufacturing services, shaping the future of the production industry.

Discover higher levels of process efficiency and agility with our manufacturing services, shaping the future of the production industry.

Global Trade

Seizing Global Opportunities with Local Expertise:

Optimizing Trade for Your Business Success

Optimizing Trade for Your Business Success

Credit Flow

Pioneering Growth Opportunities, Securing Supply:

Unlocking Business Potential through Smart Supply Chain Financing

Unlocking Business Potential through Smart Supply Chain Financing

Free Online Consultation with Product Specialists

Resolve Your Challenges with a Free Online Consultation Now

Partnership

Stay Connected with All Your Friends

Exciting Programs from Fajar Benua Industries to Provide Daily Benefits for You.

Register as a Vendor

Inviting suppliers of goods/services to become registered partners at Fajar Benua Industries

Affiliate Program

Earn passive income from affiliates by

referencing products and services from Fajar Benua Industries.

referencing products and services from Fajar Benua Industries.

Collaboration

We welcome various collaborations such as community partners, media partners, product vendors, and more.

Why Fajar Benua Industries

Online Offers

Request Documents are available online and can be easily printed

Sales Assistant

Our Sales Team is always ready to assist you for a comfortable shopping experience

TOP Program

Shopping solutions with term payments tailored to your preferences

Payment Methods

There are various convenient payment method options available.