PTFE Lining Experience List at Fajar Benua

Over the past 20 years, Fajar Benua Group has grown into a stable, independent, medium-sized, and successful industrial company both nationally and internationally. Currently, there are approximately 300 employees at Fajar Benua Group, and among our expertise is in designing highly corrosion-resistant piping networks. We are market leaders in this field because we consistently drive innovation and set standards with our processing techniques.

Our customers come from various industrial sectors, including the chemical industry, pulp and paper industry, power industry, oil and gas industry, mining industry, water treatment industry, and many more. Our technology, knowledge, and experience make us a competent partner for corrosion-resistant lining systems, both in piping and in vessels/storage tanks, ensuring smooth and safe operations.

What is the Solution to Protect Your Valuable Assets?

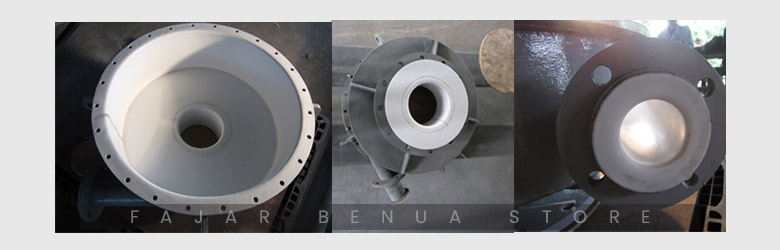

PTFE Lining Provide protection and prevent direct contact with corrosive media, extending the lifespan of your equipment. Hardware or metal parts will only serve to withstand the internal pressure of the media.

Material lining is inserted or bonded to your equipment that comes into direct contact with heavy media such as sulfuric acid. Acid, Chorine, HCL, Wastewater, and others.

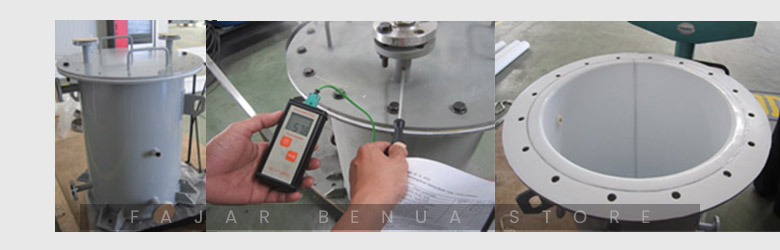

Advanced technology, extensive knowledge of innovative materials, and long-term cooperation with qualified suppliers—these are what make us a competent partner in piping systems, especially in providing highly corrosion-resistant protection.

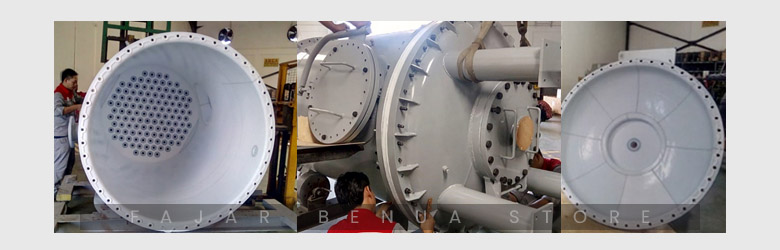

Focused on the highest quality and future-oriented innovation, Star Guardian, as a PTFE Lining product brand, offers the best protection for your equipment against corrosion and contamination in piping systems, fittings, valves, and tanks. Designed with fluoropolymer-metal fusion technology, it extends the service life of your equipment and reduces maintenance costs.

With Facilities

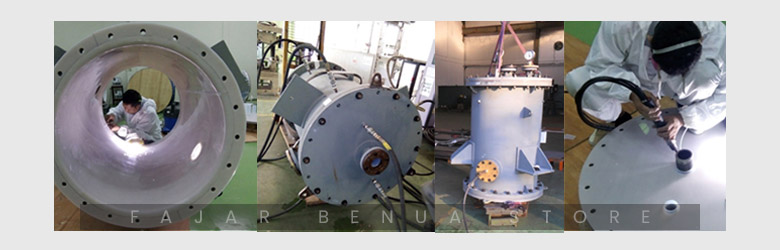

- Clean Room Facililty

- Highly Customizable

- PTFE Pipe Lining from 0.5″ to 12″ [inserted].

- PVDF, PP, HDPE etc Pipe

- Lined pipe fitting such as elbow, tee, cross tee, reducer, etc.

- Plastic lined for tank or vessel

Below is a list of Fajar Benua Group's experience in PTFE Lining.

Experience List

Equipment : Column

Material Lining : PP

Temp. Max : 80 Deg C

Medium : HCL5% + Liquid Resin

Equipment : Vessel

Material Lining : PFA

Temp. Max : 63 Deg C

Medium : EDC Chemical (Ethyl Dimethylaminopropyl Carbodiimide)

Equipment : Mixing

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : HcL 35%

Equipment : Tank

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : H2SO4

Equipment : Storage Tank

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : H2SO4

Water Treatment Plant Project

Mixer

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : Bubble Gel

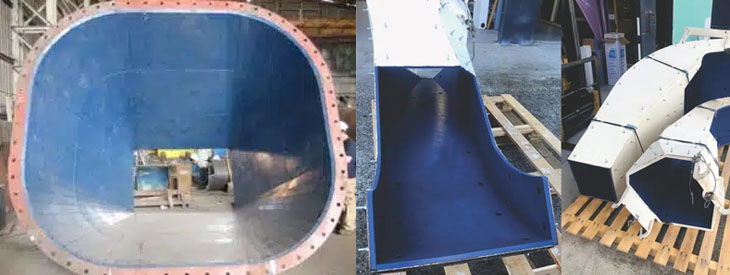

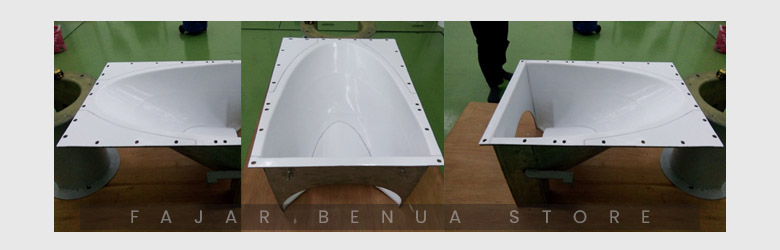

Equipment : Hooper

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : Alumina Powder

Equipment : Chute

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : Pasta

Equipment : Tank

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : H2SO4

Equipment : Neutralization Tank

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : Acid + Water

Equipment : Vessel

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : HCL 35%

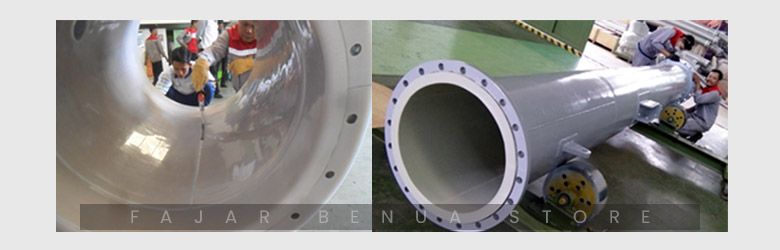

Equipment : Piping and Fitting

Material Lining : PTFE

Temp. Max : 60 Deg C

Medium : Sea Water

Equipment : Piping & Fitting

Material Lining : PTFE

Temp. Max : 35 Deg C

Medium : H2SO4 98%

Equipment : Custom Tee

Material Lining : PTFE

Temp. Max : 70 Deg C

Medium : HcL

Part PVDF

Newsletter

Enter your email address to join Newsletter Fajar Benua Store