Introduction Guide

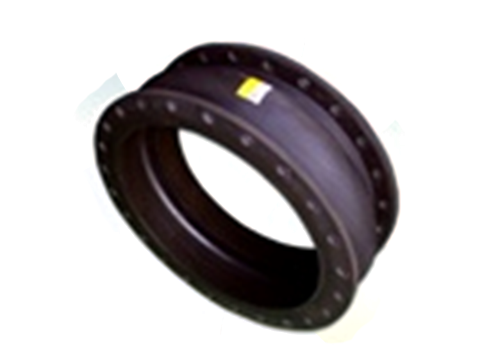

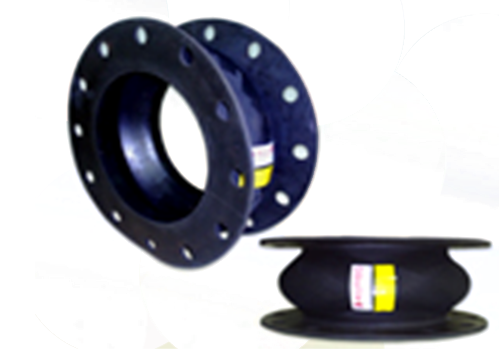

Expansion Joint Rubber

Flexible Connectors made from elastomer and natural and/or synthetic fabric, designed to relieve stress in piping systems caused by thermal movement and mechanical vibration.

There are many material choices based on the area of use for expansion joints Rubber expansion joints also have advantages and disadvantages compared to metal expansion joints. Rubber expansion joints can absorb large movements over very short distances.They provide all directional movements, such as axial, angular, lateral, and torsional, that may occur due to external conditions.

These Rubber Expansion Joints are widely used in industries such as:

Water pipes, Desalination plants, Compressors, Blowers and fans, Cement industry, Chemical industry, Glass industy, Wood-processing industry, Pulp and paper industry, Railed vehicles, Refineries, Shipbuilding, Steel mills, Sugar industry

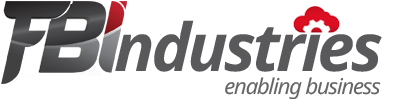

Types of Rubber Expansion Joints

Wide Arch Type

“L” shaped flange design

Floating flange

UG type-Loose flange

UG type-Full faced flange

Underwater application

Reducer – Concentric

Reducer Eccentric

Molded Extra Wide Arch

Flowing Arch

Sleeve Type

Demounting Design

Flexible Connector

Pipe / Pump Connector

Flue Duct Connector

SuperFlex Connector

Elbow Connector-45/90 deg

Rectangular Type – “U” Design and Arch Design

Rectangular Type – “U” Design and Arch Design

High Quality Expansion Joint Rubber

Suitable for High Temperature Applications

High Movement Ability

Low Cost and Fast Delivery

Long Service Life

Our Experts Will Provide for Your Rubber Expansion Joint Needs

For specific criteria requests for applications and other system designs, feel free to discuss with us online or send your request directly.